FLUORESCENT PENETRANT INSPECTION (FPI)

Background

FPI (Fluorescent Penetrant Inspection) test is a widely applied method used to locate surface-breaking defects in all non-porous materials (metals, plastics or ceramics). FPI is used to detect casting and forging defects, cracks, leaks in new products and fatigue cracks on in-service components.

FPI is based upon capillary action, where low-surface-tension fluid penetrates into clean and dry surface-breaking discontinuities. FPI Fluorescent Penetrant may be applied to the test component by dipping, spraying or brushing. After adequate penetration time has been allowed, the excess penetrant is removed and a developer is applied. The developer helps to draw penetrant out of the flaw, where a visible indication becomes visible to the inspector. Penetrant Inspection is performed under ultraviolet light.

This is the process to locate a section of material with a surface-breaking crack that is not visible to the naked eye:

- Penetrant is applied to the surface.

- Excess penetrant is removed.

- A developer is applied, rendering the crack visible.

Contact Us for Your FPI System

The main steps of the Fluorescent Penetrant Inspection process are:

1. PRE-CLEANING

The test surface is cleaned to remove any dirt, paint, oil, grease or any loose scale that could either keep penetrant out of a defect or cause irrelevant or false indications. The end goal of this step is a clean surface where any defects present are open to the surface, dry and free of contamination.

Surface preparation prior to liquid penetrant application, in accordance with ASTME 1417, requires:

“All surfaces to be examined shall be clean, dry, and fee of soils, oil, grease, paint and other coatings, corrosion products, scale, smeared metal, welding flux, chemical residues, or any other material that could prevent the penetrant from entering discontinuities, suppress dye performance, or produce unacceptable background.”

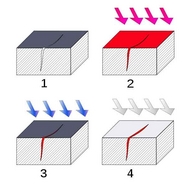

2. APPLICATION OF PENETRANT

The penetrant is then applied to the surface of the item being tested. The penetrant is allowed time to soak into any flaws. The soak time mainly depends on the material being tested and the size of the flaws sought.

3. EXCESS PENETRANT REMOVAL

The excess penetrant is then removed from the surface. The removal method is determined by the type of penetrant used. Water-washable, solvent-removable, lipophilic post-emulsifiable or hydrophilic post-emulsifiable are common choices.

This process must be performed under controlled conditions so that all the penetrant on the surface is removed (background noise), but penetrant trapped in real defects remains in place.

4. APPLICATION OF DEVELOPER

After excess penetrant has been removed, a white developer is applied to the sample. The developer should form a thin, even coating on the surface. The developer draws penetrant from defects out onto the surface to form a visible indication: a process similar to the action of blotting paper. Any colored stains indicate the positions and types of defects on the surface under inspection.

5. penetrant INSPECTION

The inspector will use visible light with adequate intensity (100 foot-candles is typical) for visible dye penetrant. Ultraviolet (UV-A) radiation of adequate intensity (1,000 micro-watts per centimeter squared is common), along with low ambient light levels (less than 2 foot-candles) for FPI Fluorescent Penetrant examinations.

Inspection of the test surface should take place after 10-minute development time. This time delay allows the blotting action to occur. The inspector may observe the sample for indication formation when using visible dye, but this should not be done when using fluorescent penetrant.

Also of concern: if one waits too long after development, the indications may “bleed out” and hinder interpretation.

Fully Automated Pre-Cleaning and Semi-Automated FPI System

The FPI equipment system below incorporates a fully automatic Ram Tough wash-rinse-dry system prior to a semi-automated FPI module. The application is for water-washable penetrant like ASTM E 1417. The process consists of seven steps :

- Pre-clean

- Rinse

- Dry

- Penetrant – Dwell

- Water Wash

- Hot Air Dry

- Developer.

The line runs right to left. This fluorescent penetrant inspection system processes multiple bearings loaded into baskets. The parts are first thoroughly washed, rinsed and dried using an automated AMKD16EWRD Console System.

FPI Console

The baskets are taken from the unload station of the automated system and placed on the first transport elevator of the second semi-automated console system for individual penetrant, wash and dry stages.

The FPI rinsing module includes strategically placed spray headers (specific nozzle locations and patterns) with zoned platform oscillation between the headers to effectively remove penetrant. Adequate hot water is brought to the system within the temperature and pressure limits set by specifications on the penetrant removal. Water detailing and air blow-off guns are used to ensure that any final traces of penetrant and excess water have been removed respectively prior to the hot air knife drying.

Fully Automated Dye Penetrant Systems

This Fully Automatic Dye Penetrant System was designed for ceramic bearings. The bearings of this piece of FPI machinery are processed in batches of 100 in a fully automated system using transport/oscillating elevators as the basic building block for each of the stages. The bearings are processed through the penetrant application, excess penetrant removal and hot air knife dryer as per specifications. Exclusive features include multiple rollover, multiport oscillation, ram tough automation, and multizone spray. Designed for manual or fully automated systems to accommodate water-soluble or oil-based penetrant processes. Contact Advanced Deburring & Finishing for your Fluorescent Penetrant Inspection machine today!