About Filtration and Water Recovery Systems

Many industries remain dependent on processes that produce wastewater. Industrial wastewater treatment involves processes that remove contaminants such as oils, dissolved heavy metals, suspended solids and organic compounds prior to reuse or its release into the environment.

Filtration systems, water recovery techniques and treatment requirements vary from state to state and from municipality to municipality. Most local authorities specify acceptable criteria for pH, biological oxygen demand (BOD) and chemical oxygen demand (COD). Criteria will be noted on your discharge permit.

Tramp oils can be recovered with skimming devices and coalescers. Filtration systems and sedimentation are used to remove solids. Centrifugation is a highly accelerated form of sedimentation.

Contact Us for Your Filtrations and Water Recovery System

Most industries produce some wet waste, although recent trends have been to minimize such production or to engage in recycling. Recycling is popular and becoming more important for our environment every day.

Industrial wastewater treatment and water recovery cover the mechanisms and processes used to treat water that has been contaminated in some way, through industrial or commercial activities, prior to its release or re-use.

At Advanced Deburring & Finishing, we serve industries such as:

- Agriculture

- Iron and steel

- Mines and quarries

- Food production

- Chemical production and use

- Nuclear

- Basic water treatment

Vibratory finishing and parts washing both greatly benefit when filtration and water recovery are used in conjunction with these processes.

With so many different methods of industrial water recovery, companies today need thorough research and an experienced partner to find the correct system for their requirements. There is a variety of designs of systems for water recovery that can be used. For example, settling tanks and bag or cartridge-type filtration systems are great for smaller applications. For more intensive operations, there are papered filters, centrifugal units, cyclonic-style filtration and ultra-filtration systems.

For the most demanding requirements when it comes to re-use and ppm, there is reverse-osmosis mechanical vapor recondensing or steam water recovery.

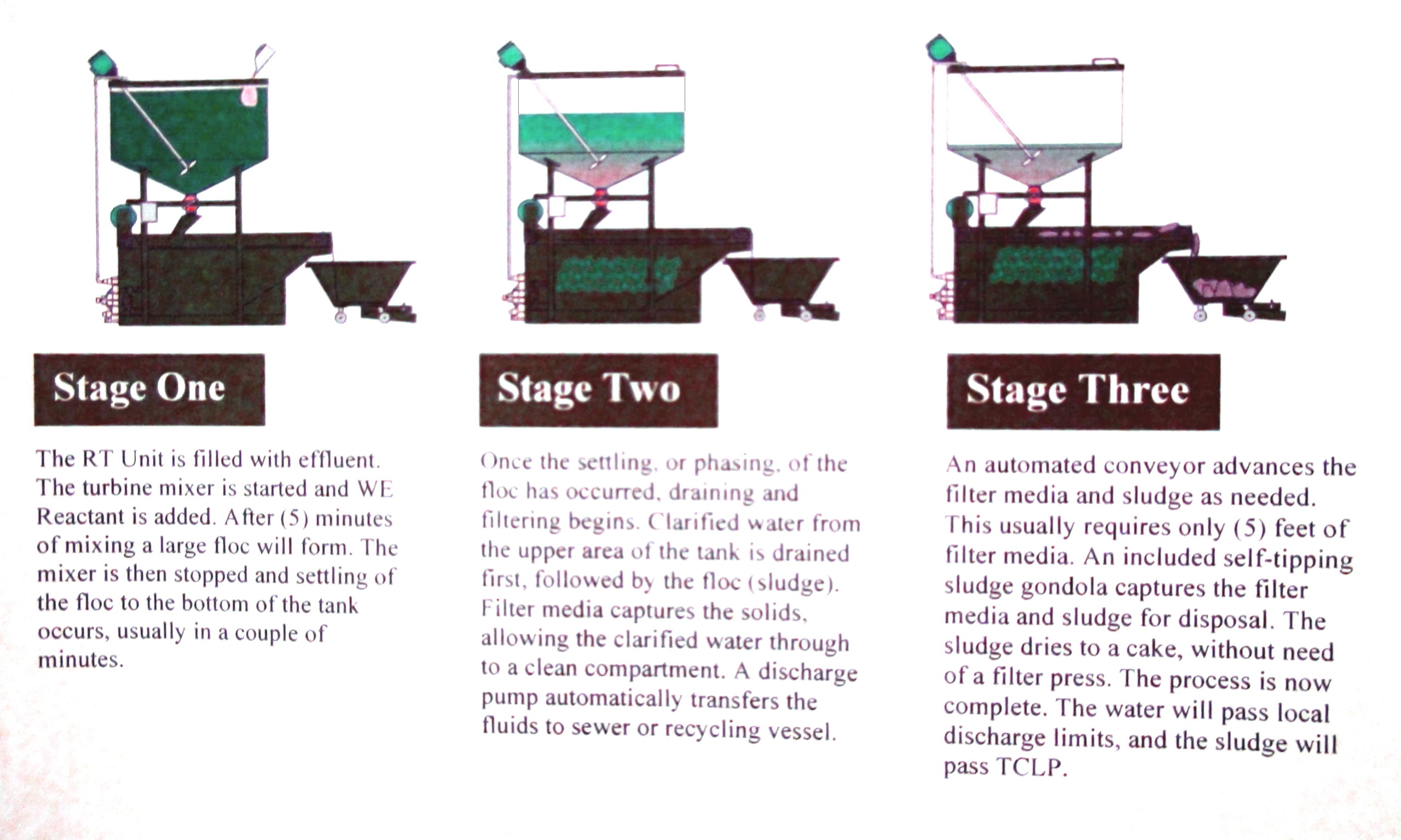

This process of water recovery goes from gravity bed/bag type systems to benenite clay processing units and that meets local sewer discharge needs, an excellent choice for recycling, compact design and a separation system. Once the clay hardens it can be used for simple disposal because it will pass the Toxicity Characteristic Leaching Procedure (TCLP).

Batch sizes from 65 gallons to 500 gallons

What is a Ultrafiltration System

Ultrafiltration (UF) is the removal of oils and solids with membrane technology.

How it works:

- Wastewater containing micron size solids and emulsified oils is pumped through the membrane filter(s) at high rates and under pressure. The UF membrane allows water and other low molecular weight substances (soaps, salts and ppm surfactants) to pass through micro openings to exit the system as a permeate.

- Higher molecular weight substances such as solids/oils are retained and held in the system.

- There are maintenance and operational cost on this type of system to allow it to run at maximum performance, but it can be cost-saving by removing 50% or plus of dirt from your wastewater.

What is an Autovac Filter

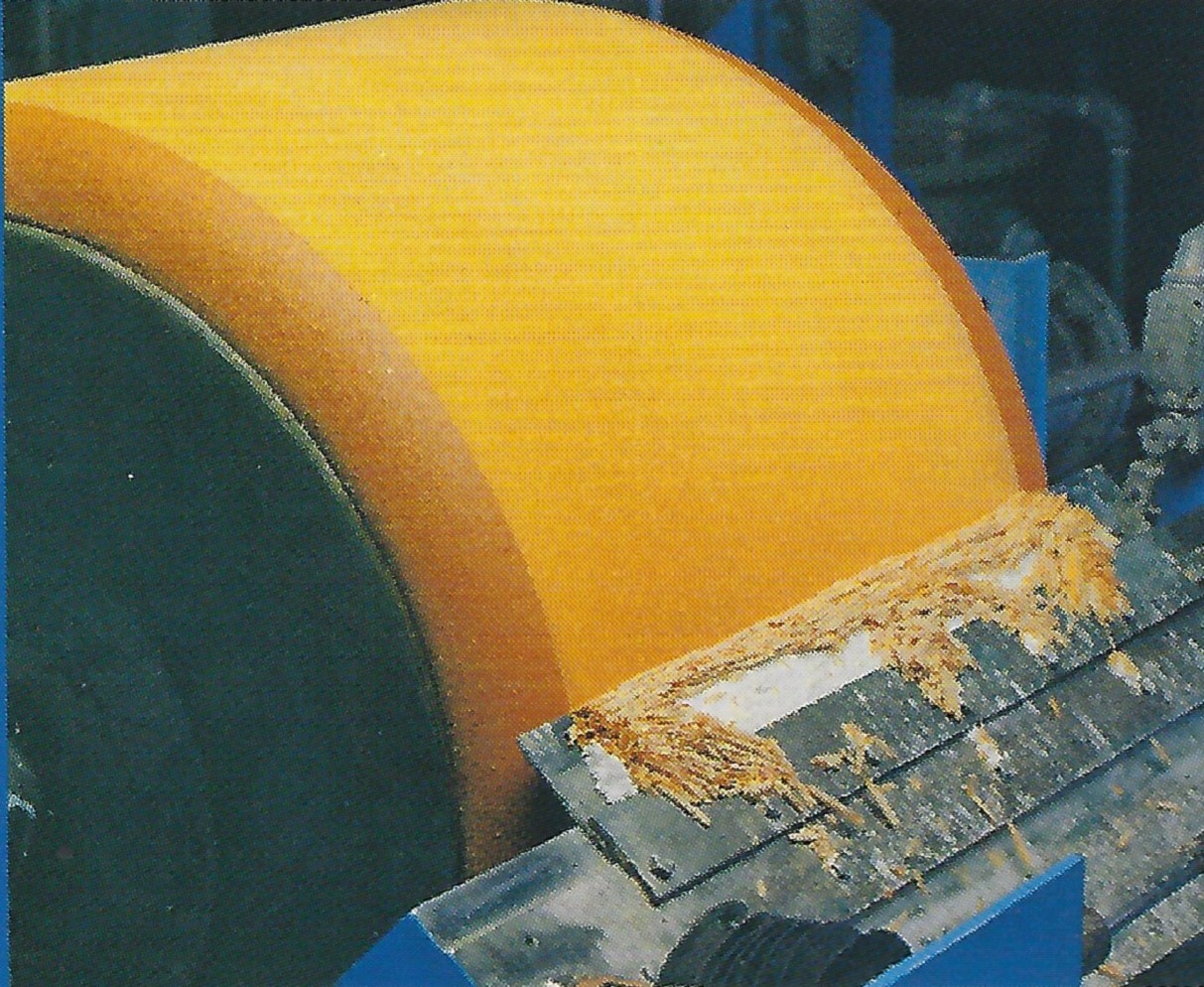

A self-contained dewatering system that filters industrial sludges down to 1/2 micron.

How it works:

- The AutoVac Filter separates sludges into solids and water which can be typically disposed of in sewers or recycled. Pre-piped, pre-wired and skid mounted, the AutoVac is easily added to any manufacturing or processing facility.

- As water is vacuumed through a filter media, solids accumulate on the filter drum’s surface with lathe-like precision. The solids simply fall off and into a standard dumpster.

Advanced Deburring & Finishing offers a guaranteed process for your wastewater recycling. Extend your solution’s life with lower waste volumes and disposal cost. Contact Advanced Deburring & Finishing.