Last updated on February 16th, 2021 at 03:19 pm

Oil skimmers

Maintaining the Best Bath Conditions

Choose Advanced Deburring & Finishing for optimum cleaning processes with the reliability to continue all the time and produce the results needed or the specifications required for your finished parts production. Oil skimmers and filtration are essential for your processes and procedures.

Oil removal systems are standard features that can easily be added to any of our cleaning systems. Our trademark “surface sweep” system is designed to trap oil in an off-line quiet tank from lateral flow across the surface tank. The cleaning solution is closed-loop from the tank, and the tank is quiet while in operation. It “cleans the solution while the solution cleans your parts.”

Contact Us for Your Oil Skimmer

Standard Filtration

Standard filtration is available on every system and should be utilized for the longevity of both the solution and the parts.

There are many different setup types available depending on the application:

- We offer simple 4×6 vessels to 8×30 and larger depending on volume.

- Micron size ratings of 3 to 5 microns, up to 400 microns with three different types.

- Two different bag styles with poly or cotton and one for very tight specifications.

The filter can be stacked in line or with a diverter valve setup so there’s no machine downtime with filter change-outs.

Polishing your bath water can greatly help extend bath life. This saves water, soap, time and energy. Our oil skimmers and other products are designed to save you money.

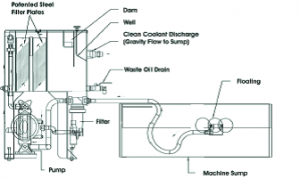

Tramp Oil System

“Oil contamination is the number one cause of metalworking fluid disposal.”

Phasep’s patented oil removal technology will improve metalworking fluid and bath life by at least 100%, drastically reducing the need for hazardous waste disposal.

For most applications, a dedicated unit provides the maximum oil removal for the investment. The “mini” and “junior” units process sumps for 40 to 200 gallons larger waste treatment and central coolant water systems up to 400 gallons can design and have done.

Our unique and patented metal plate design packs for coalescing require very low maintenance, so little time is spent keeping the unit at peak performance.

Most commonly, the applications are machine coolant and parts and washers. It can be used anywhere there are two distinct phases of liquid (i.e. oil and water).

Applying the Phasep system is very straightforward. The two easiest ways to determine whether this coalescing unit can be used to separate two liquids are as follows:

- Visually inspect the liquid in the tank or sump. Is there is a visible oil layer in the system/tank floating on the surface? With a very light finger, touch the surface. The oil will stick and you’ll be able to feel the lubricity when you rub your fingers together.

- Take a sample (approximately 10 to 16 oz.) of solution in a clean container. Let the liquid rest for a clear 10 to 15 minutes. If there are distinctly visible phrases of liquid (separation levels) present in the sample, Phasep will work to separate the solutions.

For even more information about oil skimmers and related technologies, contact Advanced Deburring & Finishing today.