Last updated on July 1st, 2025 at 06:52 pm

Ultrasonic cleaning and deburring machines are ideal for industrial, medical, automotive and other applications. They’re powerful, quiet and more precise than hand-scrubbing or other forms of line-of-sight cleaning devices like power washers. Whether you need to degrease an anilox roller, chrome-plated cylinder or automotive part, Advanced Deburring & Finishing will have the equipment to meet your size and power specifications.

Ultrasonic Cleaning Systems for Specialty Parts

Two-Stage Units:

- Vapor/Immersion

- Vapor/Immersion/Ultrasonic

Cleaning Zones:

- 17″ x 11″ x 9″ Deep

- 41″ x 24″ x 18″ Deep

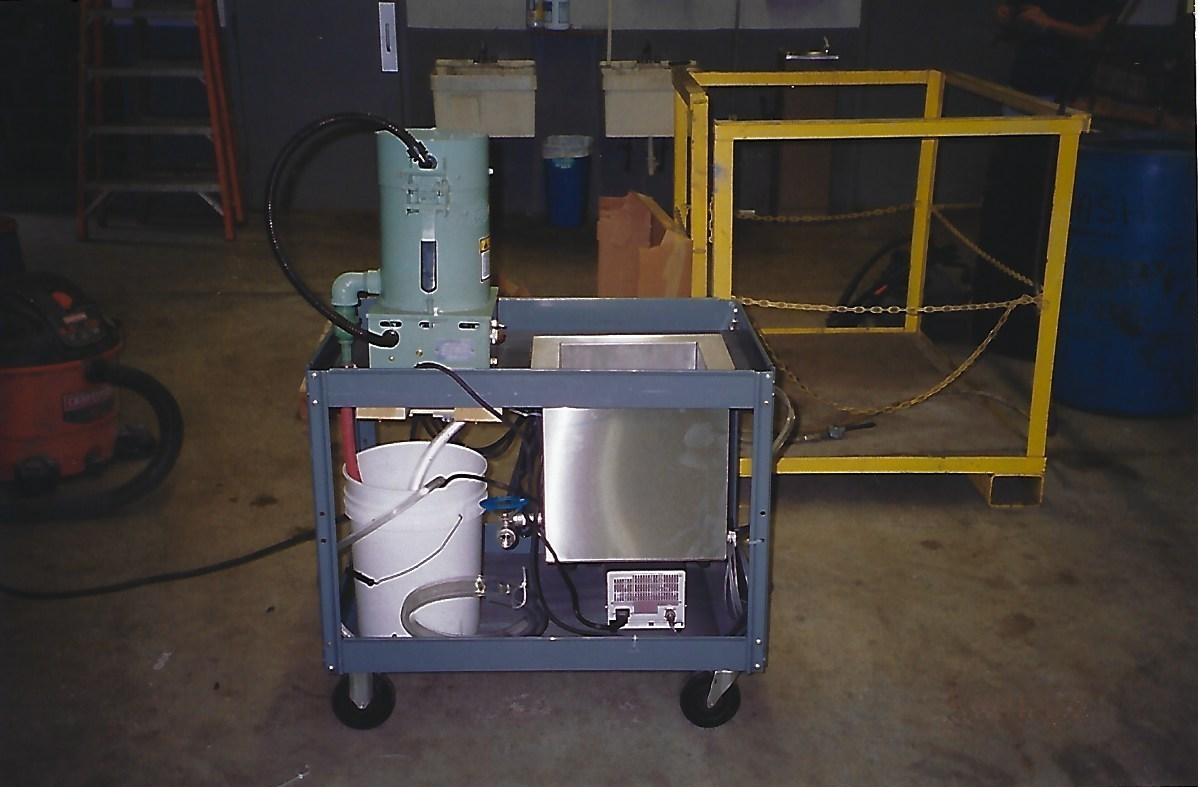

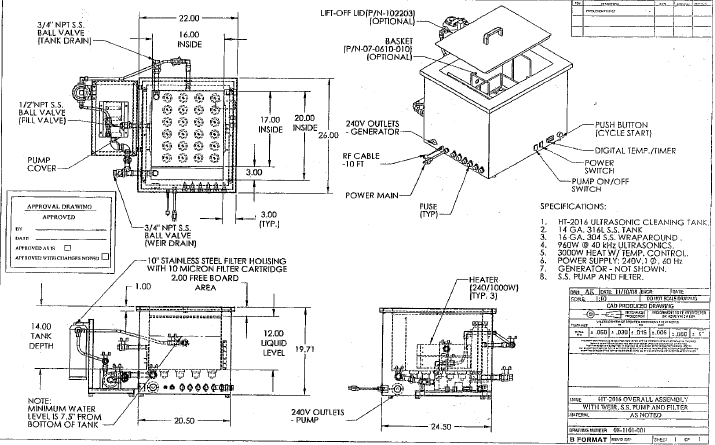

HIGH-INTENSITY SWEEP FREQUENCY ULTRASONIC CLEANING TANK SYSTEM

Includes:

- Stainless construction

- High-efficiency piezoelectric transducers

- Modular design with separate generator

- Sweep frequency power oscillation

- FCC-compliant with EMI suppression

- Many standard tank sizes available

“Band Scanner” technology is the benchmark for efficiency and reliability among industrial ultrasonic tank/generator systems. We offer 2.5 to 60-gallon capacity ultrasonic deburring cleaning tank systems with the widest range of operating frequencies and variable output in watts. Plus, these heavy-duty units can handle the harshest industrial environments.

- Table-top-ready

- Filtering systems

- Oil skimming

- Sonic power from 225 to 2400 watts

- Baskets, covers and insert trays

Contact Us for Your Ultrasonic Cleaning System

ANILOX “CY” SERIES ULTRASONIC CLEANING

The Anilox Cleaning System uses advanced ultrasonic technology to deep-clean anilox rolls without compromising the integrity of fine cell walls, even on high-screen-count rolls. It is also highly effective on chrome-plated cylinders, offering superior cleaning that’s faster and more efficient than traditional roll cleaning methods.

Critical process time, temperature and ultrasonic cleaning intensity are all carefully controlled to optimize cleaning and ensure process consistency.

- CY-4808: 20 gal. x 48 x 4 x 18″ tank @ 900 watts

- CY-14414: 225 gal. x 144 x 18 x 26″ tank @ 7200 watts

We have a proven process and procedure with many systems in operation today.

Sample part evaluations and/or processing sample parts is recommended for most applications.

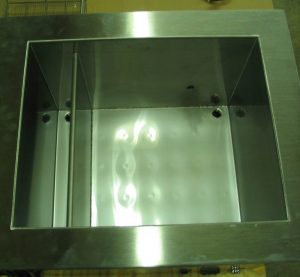

MULTI-STAGE CONSOLE UNITS

These systems offer an attractive, space-saving alternative to industrial parts washing systems. They’re built with an all-stainless (brushed finish) cabinet, seamless countertop, tanks and supply plumbing.

Perfect where appearance and maintenance cleaning are particularly important.

- Medical instruments in hospitals

- Pharmaceutical plants

- Printing shops

The “CU” Series is modular and expandable. Small portable systems are available.

Tank Sizes:

- 10 x 12

- 12 x 16

- 16 x 20

- 20 x 24

100%Pneumatic Powered systems for solvent cleaning/dips

visit Specialty Systems

SOLVENT AND VAPOR DEGREASER SYSTEMS

For applications that require low-flashpoint solvents.

Designed for hazardous environments, the “D” Series is state-of-the-art ultrasonic cleaning technology with emissions control and operator safety features. It is fully enclosed, with automation for basket loading and unloading. Features extended freeboard, sliding cover, water separator and “vapor watch” safety circuit for sensors, and monitoring system functions for identifying faults and delivering operator notifications on machine procedures.

About Our UltraSonic Cleaning Services

At Advanced Deburring & Finishing, we’re experts. We resolve the effects slow, ineffective cleaning processes can have on a company’s bottom line. Our team ensures you receive the right solutions, finding the right cleaning process and equipment for your material’s needs. We can help you cut costs while creating the highest-quality finishing.

Comprehensive Ultrasonic Cleaning and Deburring Services

Selecting the correct ultrasonic cleaning and deburring method for your product is a vital part of the cleaning process. The foundational step is assessing the type of material you need to clean and what substance you need to remove. Although the cleaning process can seem complex, it’s reassuring to know there is a specialized science behind choosing the correct solution for objects used in medical or dental practices. Various formulas are tailored to these specific needs when doing industrial parts cleaning.

Specific types of cleaners are made to help remove difficult substances like oil, grease or carbon residue. The ultimate goal is to use a solution with the highest-quality active ingredients. We also offer immersion ultrasonic solutions.

Sonic Action (Cavitation)

Typical ultrasonic cleaning frequencies range from 20 to 200 kHz. The standard operating range of a variable frequency ultrasonic cleaner is 30 kHz for a magnetostrictive transducer with piezoelectric. “Normal” is 40 kHz, with up to 80 kHz in standard units.

A piezoelectric transducer can accommodate the entire frequency range necessary for various cleaning requirements. It’s also power-efficient because it converts low-voltage electrical energy into mechanical energy, consuming less power than transducers that require the expansion and contraction of metals like copper. Since it’s powered by a crystal called lead zirconate titanate, a piezoelectric transducer is quiet, making it great for areas where noise levels are a concern.

The high-frequency ultrasonic cleaner design allows for waves to pass through the solution to cause cavitation, or intense microscopic air bubbles (millions of them) that make an implosion on your part surfaces or a “scrubbing action” that penetrates into cracks, recessed areas, blind holes and passageways for the ultimate precision cleaning process.

The larger the item to be cleaned — or the greater the surface-to-mass ratio — the more required ultrasonic power. That’s why it’s important that all surface areas are exposed and the controls are available for adjusting the power necessary for a proper clean.

ULTRASONIC CLEANING WITH IMMERSION/AGITATION

- Sonic power from 1000 to 3000 watts for standard machines.

Model: MKD-16EUSSWR

Ultrasonic Wash and Rinse, Heated Tanks

- Control Panel on Left

- Sonic Generator Stand on Right

- Open Platform/Roller Conveyor Design for Direct Sonic Import

Solvent-Free Cleaning Solution

Ultrasonic cleaning often uses solutions made from a solvent-free, water-based degreaser. This type of solution can clean most metals, including stainless and carbon steel, magnesium, brass, copper and more. It’s also effective for most composite materials, including plastics and ceramics. These aqueous solutions are user-friendly, especially when compared to more difficult manual cleaning methods. The aqueous solution allows you to simply clean the item with the proper dilution.

In some scenarios, you can even heat your solution to achieve a deeper and more thorough clean through chemistry. However, it’s not recommended to heat the solution when working with composite materials like plastic because doing so can cause deformation.

Solvent-free solutions are ideal for industrial parts cleaning that targets the oils, stains and greases that develop on certain metals. For example, stainless steel, magnesium, brass and even 3D printing parts can benefit from a water-based solution. These solutions are the perfect complement to your ultrasonic cleaning and deburring machine in a wide variety of cleaning applications.

Typical cleaning applications include:

- Parts detailing

- Metal finishing

- Pre-treating

- Parts finishing

- Degreasing

- Batch processing

Enzyme-Based Cleaning Solutions

Enzyme solutions help medical and dental professionals remove different types of proteins, carbohydrates and fats from instruments and medical equipment.

Common examples of substances enzymes can remove include:

- Organic debris

- Organic residue

- Biofilm

- Inorganic soil

- Tissue

- Mucous

- Blood

Different enzymes attack various types of substances. There are enzymes that break down and eat blood, fat, amino acids and protein. The enzymes attack the protein chain found in these substances at a molecular level and help prevent infection. Enzymes are safe for use on aluminum, glass, rubber, plastic and stainless steel.

Contact Advanced Deburring & Finishing About Ultrasonic Cleaning Systems

Manufacturing and production engineers trust Advanced Deburring & Finishing for precision-engineered ultrasonic deburring and cleaning machines and services. With locations in Pennsylvania and North Carolina, we deliver consistent, reliable results backed by decades of experience.

Increase your margins and save your time while producing high-quality work with the help of our ultrasonic cleaning and deburring solutions.

Contact Advanced Deburring & Finishing today to learn more about our ultrasonic cleaning and deburring machines.