Heavy-Duty Washers

Typhoon HD Heavy-Duty Turntable Spray Washers &

AJA-kleen heavy-duty agitation washers

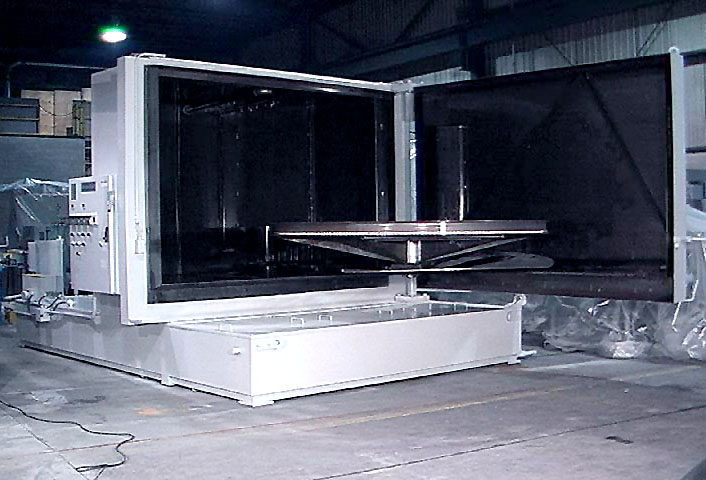

Typhoon HD turntable spray cabinet washers are designed to clean large parts placed directly on a retractable turntable or batches of small parts loaded in baskets. This heavy-duty washer combines pressure, heat and aqueous cleaning solutions to clean and degrease your parts to spec within minutes. Other processes such as surface treatment and phosphating can also be performed in this solution.

Typhoon HD’s design features a large solution tank volume to reduce the likelihood of foaming due to reduced agitation by pumping action, and to help to settle contamination. This also reduces the tank clean-out frequency. Many other design features such as low-maintenance pumps, digital temperature controllers, and cycle timers are standard on turntable parts washers. These cabinet washers can also be easily customized by adding needed features selected from over 40 pre-engineered options.

Contact Us for Your Heavy Duty Washer

The Typhoon HD model is available in a single- or multi-stage configuration, integrating up to four independent recirculated stages. Each recirculated stage has a dedicated tank, heating system, circulation pump, cycle controls and spray manifolds in the main spray cabinet.

Typhoon HD is an ideal aqueous parts washer for in-process and final cleaning in maintenance, manufacturing and remanufacturing applications.

Turntable -Standard Dimensions

| Turntable Diameter | Work Height | Weight Capacity | Processing Stages | Heating Methods |

|---|---|---|---|---|

| 28" | 36" | 1000 lbs | Wash Rinse 2nd Rinse Blow-off | Electric Gas Steam |

| 42" | 48" | 2500 lbs | ||

| 50" | 60" | 6000 lbs | ||

| 62" | 72" | 10,000 lbs | ||

| 75" | 84" | 20,000 lbs |

We offer the best heavy-duty washers for heavy manufacturing with cumbersome and/or large parts to process. 43 pre-engineered optional features are available along with thousands of different configurations for the application, proving our designs and durability. Ideal for remanufacturing and heavy maintenance on very dirty (oil or grease) parts. Facilitates rust, stripping and paint removal.

A cellular concept provides the smallest footprint with a single point for loading and unloading. The Typhoon RW rotary turntable power spray washer is ideally suited for operations in a lean manufacturing environment.

The part is placed on a rotating table or indexing table to travel through this multistage system. Wash, rinse and dry using variable-speed units at between 1 and 6 feet per minute.

It can achieve precise spraying for critical parts and part areas and is easy to set for automatic operation.

Typhoon HD is a high-end, robust machine designed to outperform and outlast all of the others on the market. It’s possible to get 35-plus years on a machine running a 16-hour workday for six days a week.

These are engineer-driven machines with no compromises in operator safety and reliability. It boasts a minimum 4:1 safety factor, plus extra-large tanks and heavy-duty components.

Typhoon HD offers maintenance-free door seals with a labyrinth design. Chip trays and pump screens join our low NPSH vertical processing pumps. These are much more reliable over time than high-rpm pumps.

Standard spray pressures range from 60-70 PSI to 200 PSI.

With heavy cleaning applications, there’s likely a fair amount of waste or dirt to remove from part surfaces. Filtration systems and bottom sweeps can play an important role in maintaining bath longevity and tank cleanouts. A tank drag-out unit can get the gross contaminants that want to settle out on the bottom of the tank quickly.

We develop turnkey solutions that go beyond heavy-duty washers and cleaning, seamlessly integrating a wide range of processes and advanced features that dramatically improve productivity and profitability.

We deliver superior performance and reliability year in and year out for a multitude of cleaning systems, including turntable, rotary basket systems and in-line conveyor systems.

Applications:

• Rail and transit

• Aviation

• Dunnage

• Engine Block Cleaning

With so many cleaning methods and technologies on the market sample part evaluation are very important to the best machinery to achieve the goal set forth.

AJA-KLEEN Heavy-Duty Agitation washers

These are CM heavy-duty immersion/agitating parts washers.

CM-72 AJA-KLEEN Heavy-Duty Agitating Washer

Enjoy more flexibility when you need it for heavy loads and parts with large dimensions and you have a serious need to clean.

Double cantilever support with 3/16″ to 1/4″ thick plate back wall for superior structural strength, to hold 500 to 8,000 pounds. UHMW sliding blocks for no metal-on-metal contact points. The workload is supported by a structural I-beam elevator. Includes automatic covers and all necessary features, including oil skimming, filters and expand-ability if you need heat to help the cleaning process. Running at 160 to 180 degrees is no sweat for our unit, but it might be for your operator if he’s too close.

We offer custom machines for sure. Most applications are customized because every cleaning application is unique to that manufacturer. Part and cleaning parameters would be essential for the proper processing procedure, contact the experts give us a call today at 800-553-7060.

| Standard CM Washers | |||

|---|---|---|---|

| Model | Platform Size | Load | Gallons |

| CM-36 EMS | 36 x 24 x 20 | 500 - 1000 lbs | 165 |

| CM-48 ESS | 45 x 31 x 20 | 500 - 1000 lbs | 255 |

| CM-60 | 56 x 31 x 27 | 1000 - 2000 lbs | 445 |

| CM-72 | 69 x 36 x 27 | 1000 - 2000 lbs | 585 |

We provide manual to semi-automatic to fully automated heavy-duty washer systems designed for your cleaning process.

Visit Specialty Systems for more information.