PLASTIC MEDIA

Trust the industry leader, Advanced Deburring & Finishing when you need help choosing or understanding the ideal applications of plastic media for vibratory or surface finishing.

What Should I Use Plastic Media For?

If you’re new to doing your own surface finishing, you may be confused about the different types of media available, particularly the role of plastic tumbling media. In what situation would you use a plastic rather than something like steel or ceramic media?

Plastic media came about to finish softer metals/alloys. Processing softer metals (i.e. aluminum, brass, bronze, etc.) The other media are heavier per cubic foot, then the concern is rolling over the burr and peening against the surface. Much harder and longer cycle times are needed to remove a peened down burr. If the burr is a parent metal it would not be a burr as identified with vibratory finishing/deburring.

If your industrial products are mostly tough steel, cast iron, and stainless products, you may want to try using a ceramic bond. However, plastic tumbling media can be just as aggressive as ceramic and even faster with cutting. The issue then is the attrition rate or rate that the media wears away. It is more costly, wears faster, and has more residue to deal with, but can provide a very nice surface profile and RA/RMS. There can be safe scrubbing action to remove deposits and build upon a plastic part surface. Deflashing or deburring plastic is a different story. All pre-made tumbling media is manufactured to wear away at a certain rate (attrition rate/how long is going to last in the machine?). The faster it wears away to more waste is generated from the process.

What Are the Benefits of Using Plastic Media Blasting for Your Parts Finishing?

The main advantage of using plastic abrasive blasting media is that it’s easier on your more sensitive surfaces and does not change the original metal surface profile under the paint.

Benefit: Not having to refinish the metal substrate prior to repainting. The finer the surface substrate with the finish the better the paint quality/appearance with the end result. The four types of plastic blasting media. Acrylic, melamine, polyester, and urea. All have their advantages and applications. The plastic media blasting process is a dry process, meaning no warping, pitting or flash rust. Dust collection is so very important today. The right collectors are needed for any blasting process. Plastic media blasting does have some special features over a standard blast unit to be able to move abrasive through the system without them clogging up. Plastic media blasting is very susceptible to moisture build-up.

Plastic Blast Media Applications

Using plastic blast media is becoming extremely popular for paint stripping, particularly in the aviation and automotive industry. All of the sheet metal used in today’s automobiles have a specified surface finish, which must be maintained for parts such as fenders, hoods and other parts of the automobile body component pieces. There are four different sizes from fine to aggressive with different Rockwell Hardness.

Plastic abrasive provides the perfect media for this situation, it is harder than the paint you may wish to remove but softer than the metal itself. Such qualities allow this type of media to easily and safely shear the paint off without damaging the part when it’s used with the proper finishing equipment.

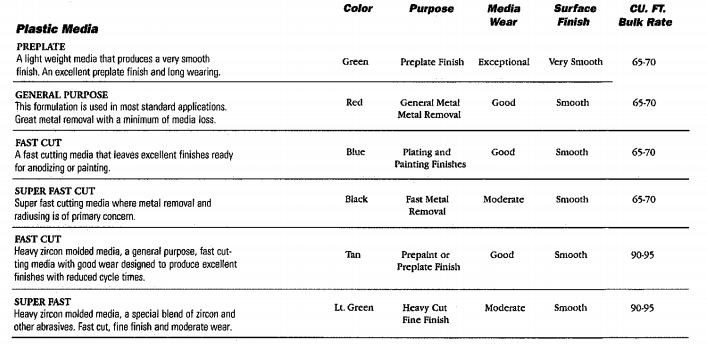

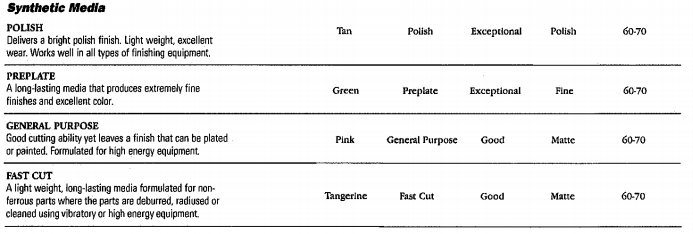

PLASTIC & SYNTHETIC MEDIA

At Advanced Deburring & Finishing, we’ll be happy to provide you with a variety of media for your finishing machines, including high-quality plastic media. Our plastic media provides the performance you require for vibratory applications. Plastic has been with us since the beginning, but there is more foam and processing concerns where residues must be rinsed of after the deburring step. Synthetic is the newer media and has less foam in the running process, but it has a little bit slower cycle time because of the breakdown rate. There are two bonds available. The many different media styles or shapes are provided in both bonds. Synthetic sells more today than the plastic.

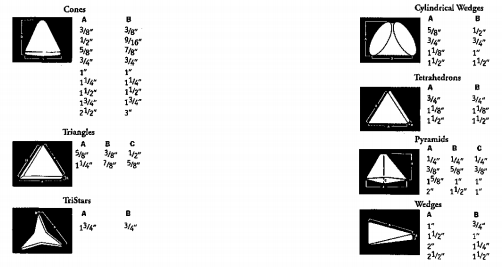

You can choose from the following plastic and synthetic media. Or, you can get in touch with us directly for further guidance. We Sell The System — not just products.