December 21, 2020

Last updated on May 17th, 2024 at 12:56 pm

Metal finishing incorporates multiple processes and serves many purposes. Manufacturers use this technique to prime metal parts for painting, remove defects, improve the appearance of a component or limit part-on-part friction. The versatility of finishing — and finishing machines — lends itself well to many manufacturing applications. However, sometimes there may be defects that are too small for you to catch — these often appear as micron-sized particles.

What is a micron, what role does it play in metal production, and how small is a micron? Read on to discover the definition of a micron, how it can affect the process of finishing metal parts and what you can do to combat it.

What Is a Micron?

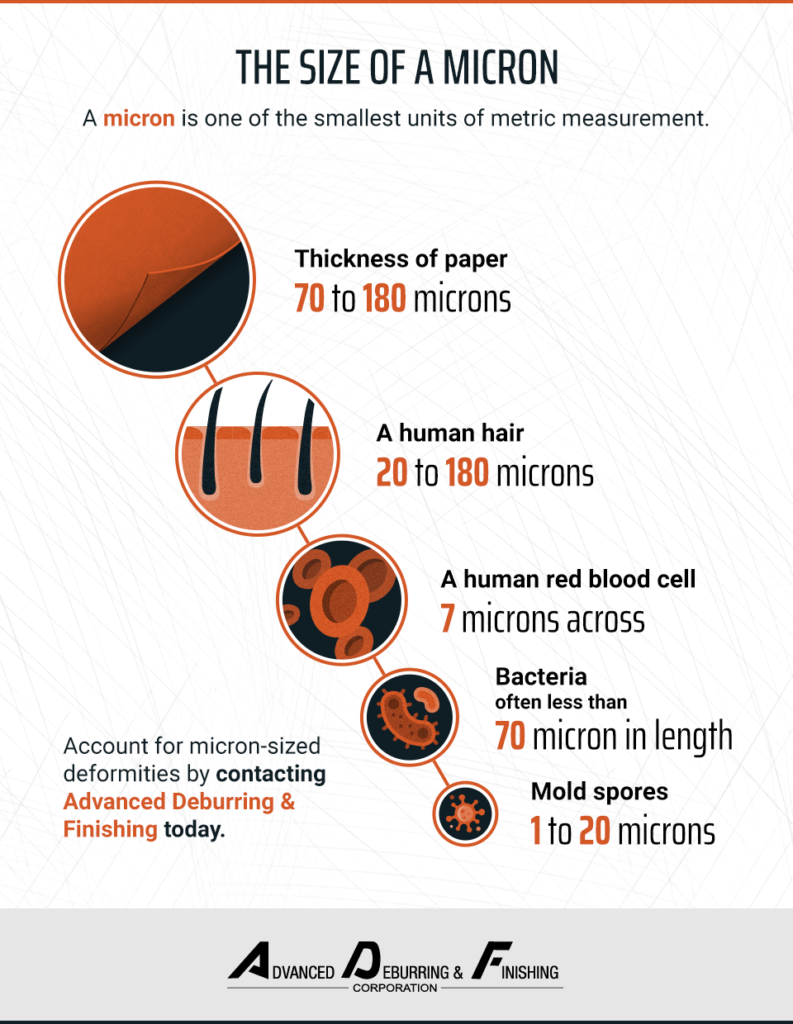

A micron — also referred to as a micrometer — is a tiny unit of metric measurement, represented by the symbol μm. Small particles such as a red blood cell, bacterium or mold spore, for example, are often measured in microns. This micron unit has many applications within various industries, though you may typically see the term describing filter media particle sizes. Regarding metal part production, items can sometimes sustain imperfections so small that they fit within the size of a micron.

Major deformities are easy to spot within the naked eye, which will tell you if a part requires a specific type of finishing process over another. However, these microscopic particles can escape your attention during pre-treatment and end up on the finished product, which can impact performance and aesthetic value. It’s best to use high-quality finishing machines for every piece you produce to prevent this from happening.

How Big Is a Micron?

Much smaller than an inch, centimeter or millimeter, microns are best to use when dealing with fine powders or particulate matter. The size of a micron is one-millionth of a meter or one-thousandth of a millimeter. Twenty-five thousand microns exist within one inch. Particles of this size are tiny and become invisible to the naked human eye once they pass a threshold of 40 microns.

Next time you ask yourself, how large is a micron? Remember, a single human hair can be anywhere from 20 to 180 microns. A piece of paper can have a thickness as small as 70 microns or as large as 180, all of which are still visible to the human eye. Bacteria are only a few microns long — often less than one — requiring powerful microscopes to view them up-close. By understanding how tiny these micron measurements can get, it’s easier to see how micron-sized particles can interfere with the metalworking process.

How Do Microns Play a Role in Metal Finishing?

Finishing processes remove the imperfections that could hinder a component’s effectiveness, both large and microscopic. It may be hard to visualize just how minuscule these particles can be, but even a tiny deformity can ruin a part. When you’re manufacturing items like jet blades or machinery gears that require ultimate precision, you want to ensure possible defects don’t fly under the radar.

Although metal components can sustain various kinds of deformities during production, a proper finishing method can eliminate these. The process starts with the cleaning and washing technique and ends with the finishing strategy itself — which can be anything from abrasive blasting to vibratory finishing. Here are a few common imperfections you may encounter when working with metal:

- Pitting: Small holes appear on the metal’s surface, which can allow bacteria to collect on material and contaminate it. Treating unpitted metal with passivation can prevent future corrosion and contamination. Nitric and citric acid cause a corrosion-resistant layer of chromium oxide to form, protecting your stainless steel from bacteria.

- Sharpness: Cutting, drilling and similar actions can create sharp edges on the metal goods you produce. Leaving these as-is runs the risk of injuring workers, and you can waste a lot of time attempting to match mating parts that won’t fit. Rounding out these sharp points creates safer components for varied uses.

- Surface contaminants: Scale, oil and mineral deposits are a few of the substances you may find on the surface of your components. You can quickly remove these by using blasting techniques, which often employ materials like sand or steel shot. Once the surface is smooth, it’s ready for any application you may have in mind.

Using the Best Machines to Clear Any Micron-Sized Deformities

To remove micron-sized deformities on your metal pieces, you need the best finishing machines to complete the job. At Advanced Deburring & Finishing, we offer multiple products to help you produce metal parts smoothly and efficiently, without imperfections. Our machines for surface finishing and refinement come in several styles with differing components:

- Round bowl vibratory machines: Vibratory finishing involves placing a manufactured part into a round bowl filled with media. The unique media flow action of our round bowl vibratory removes burrs and imperfections for smoother pieces. Round bowl units implement a gentler process, resulting in a finer surface and eliminating the possibility of part-on-part contact.

- Tub-style deburring machines: Our deburring machines use delicate or aggressive action — depending on your preference — to eliminate metal burrs that would otherwise impact the aesthetic and fit of your parts. The machine’s kinetic energy creates a fluid motion that provides significant deformity removal for a high-quality product. Tub-style deburring equipment works well with polished pieces, resulting in a bright shine.

- Slurry deburring machines: The slurry deburring machine, also known as a spindle, uses an abrasive slurry to blast away imperfections of any size, including micron-sized particles. The rotary spindle submerges the metal piece into the moving slurry, while the tub creates a velocity high enough to smoothen sharp edges.

- Continuous/thru-feed-style vibratory deburring machines: Need a device that can handle high-production tasks? Our continuous/thru-feed-style deburring machine accomplishes the job, managing anywhere from 60 to 10,000 parts an hour. Material handling systems (MHS) — which include a separate oscillation deck — are incorporated for easy media reuse. Processing cycle times range from two to 15 minutes.

Order Your Mass Finishing Machine With Advanced Deburring & Finishing

If you need a high-quality mass finishing machine to refine your metalworking, get in touch with us at Advanced Deburring & Finishing. As a leader in the finishing industry, we have been providing customers with dependable machinery since 1986. We continuously uphold our objective of providing clients with innovative products by studying new technologies and making developmental improvements.

Our experience in various industries — from aerospace to automotive — helps us give you the very best service. Prepping your surfaces with our equipment will provide a better canvas for painting, coating or reworking your metal as you see fit. No matter which phase of the process you’re on, we can assist with your finishing needs.