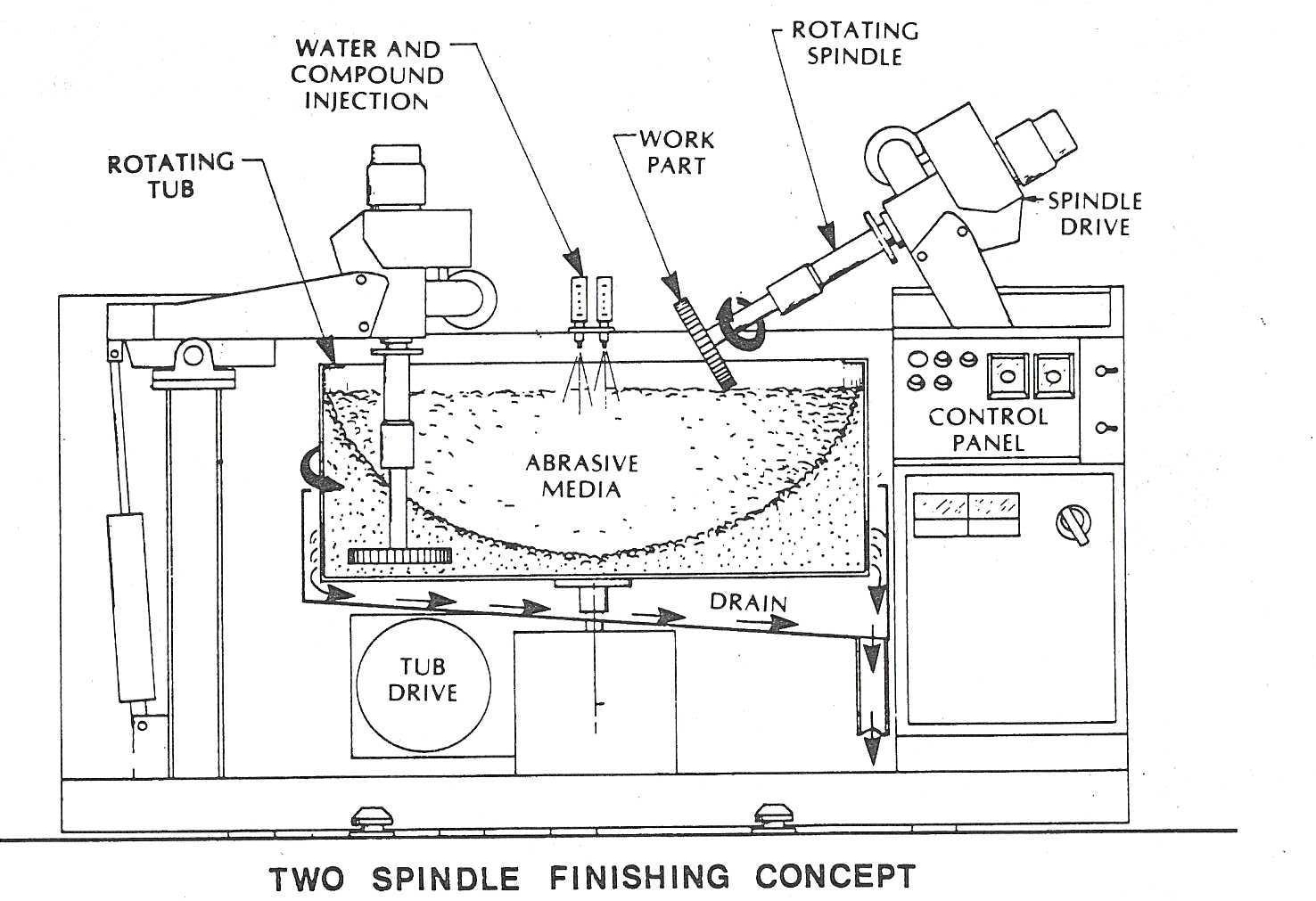

Wet blasting is a cleaning process that uses liquid to enhance a surface’s finish levels. Though it was created to mitigate the ban on silica in sand blasting, it has remained a popular finishing method due to its many advantages over the previously used method of sand blasting. However, with wet blasting systems, the abrasive and water mix is more gentle on the part surface because the water acts as a cushion.

Water acts as a buffer in the lubrication of these abrasive particles, resulting in an even flow across the surface. As a result, blasting on a delicate part can be done quickly and easily with a reduced chance of damaging the substrate. The abrasive action is consistent across the surface for an even finish.

Industrial uses for wet grit blasting include:

- General cleaning: Wet blasting can be used to clean many surfaces.

- Deflashing: Wet blasting will remove flash, the excess material on a cast, molded or forged product.

- Descaling: Water blasting removes scale and burrs without damaging the substrate material.

- Surface preparation: This process can prepare a surface for a bonding coating or hard chrome coating. It can also provide surface texturizing for a final coating.

- Remanufacturing: Wet blasting works extremely well in remanufacturing.