Last updated on December 31st, 2025 at 02:51 pm

Introduction to Tub-Style Deburring Machines

Finding dependable deburring equipment is vital for metalworking operations. Tub-style deburring machines efficiently remove burrs, polish, and finish parts for improved quality, safety, and aesthetics.

Key Questions When Getting Started

- What is a burr?

- Why is deburring necessary?

What is a Burr?

A burr is a raised edge or small piece of material that remains on a part after cutting, machining, stamping, or forming. Burrs can be sharp or uneven and may interfere with assembly, part fit, or surface quality. Removing burrs is essential for safety, precision, and a high-quality finished product.

Why Deburring is Important

Deburring with tub-style deburring machines is necessary for the following reasons:

- Creates safe edges for handling

- A better fit of mating parts

- Cosmetic appearances

- RMS/RA surface improvements

- To prepare for painting/coatings

Burr removal is critical, along with cleaning, after a vibratory/tumbling process. It directly affects part performance, reliability and longevity.

Contact Us for Your Tub-Style Deburring Machine

How Tub-Style Deburring machines Work

The variance between smeared/parent metal pushed out from a cutting tool, the thickness of flash/gates on cast parts and a simple saw cut can change a great process to a bad process with one dull or bad tool.

The variance between smeared/parent metal pushed out from a cutting tool, the thickness of flash/gates on cast parts and a simple saw cut can change a great process to a bad process with one dull or bad tool.

The kinetic energy in our tub-style deburring machines produces one smooth motion. “Roll of Mass” tub machines can be very aggressive, with heavy burr removal, because of a greater impact on the part surface and edges.

This would also tell us that the parts are okay to be in contact with other parts. Scratching may not be an issue, and even a part-on-part-only process edge break with a heavy burr can be achieved easily.

Polishing and shining of parts can also be accomplished, but processing parameters are critical to a good operation. Less gravity or smaller/softer medias could be used.

Applications & Benefits

- Compact and cost-efficient solutions for manufacturing work cells

- Handles one-part processing for both delicate and heavy burr removal

- Capable of high-luster finishes with proper part fixturing and media selection

Tub-Style Deburring Machine Models

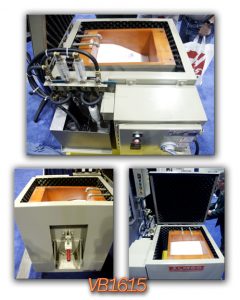

VB SERIES: 2.5 CU. FT. (1615)

- Overall dimensions: 3.6”H x 2.6”D x 2.9”W

- 3 H.P. adjustable 1750 to 250 vpm

- Tub length: 15”H x 18″D x 16”W

- Discharge door unloading height @ 17”

Available Models

There are many differently sized tub-style deburring machine models to choose from depending on part sizing, production and finishing requirements. Each one comes with 1”-thick polyurethane 80 durometer hot poured lining and sound hood.

| Model | Cu. Ft | Length | Width |

| V-5 | 5.2 | 31″ | 17″ |

| V-8 | 8.4 | 34″ | 20″ |

| V-16 | 17.1 | 97″ | 17″ |

| V-24 | 25 | 99″ | 20″ |

| V-52 | 52 | 142″ | 24″ |

Tub-Style Deburring in Action

Contact Us to Achieve High-Luster Finishes

Specialized finishes can be achieved with tub-style machines using part fixturing, roll fixtures, and proper media. Ideal for polished and burnished parts across a variety of metals.

Reach out to Advanced Deburring & Finishing for consultation, demos, or to select the right tub-style deburring machine for your operation.